High-Performance Computing for Profile Extrusion

Presentation of the problem and objective of the experiment

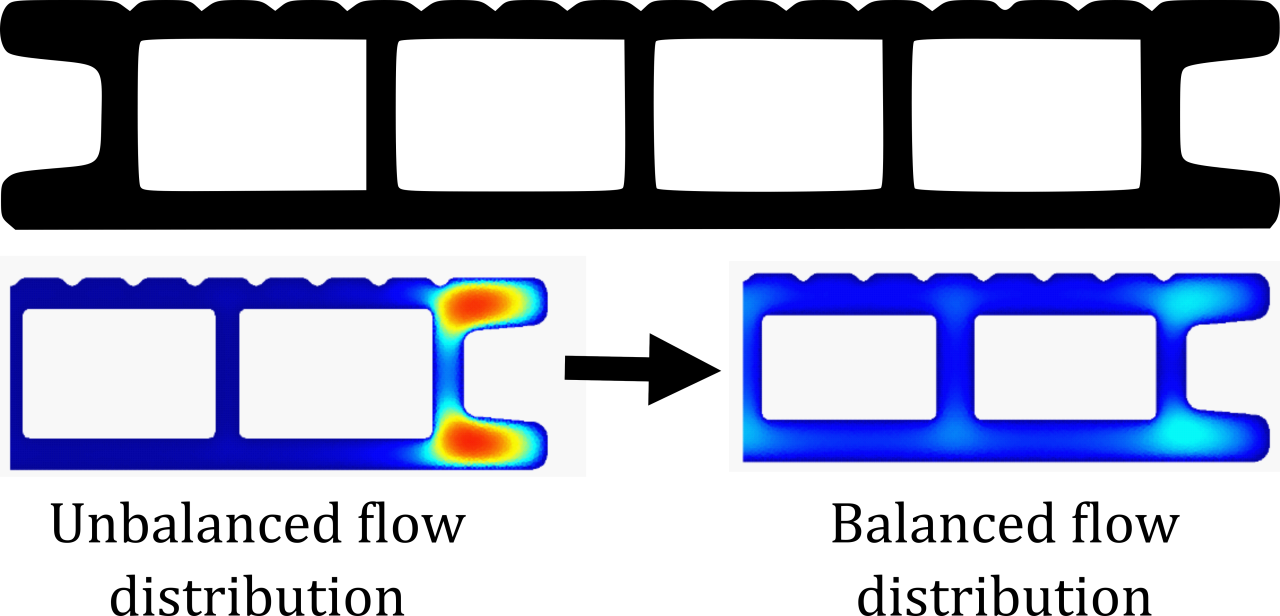

Profile extrusion is the technique employed to manufacture constant cross-section thermoplastic profiles, which has as major applications the building, automotive and healthcare industries. The design of profile extrusion dies, the components that shape the polymer melt is a very complex task, and is usually undertaken in the industry by experimental trial-and-error approaches. The employment of appropriate computational codes, able to support the design of profile extrusion dies, in an HPC framework, is expected to bring clear advantages to the final product performance, production process optimization, and time to market.

Short description of the experiment

This experiment aims at deploying a computational framework that runs efficiently in HPC facilities, intended to support design and optimization of profile extrusion dies, and reduce development costs and time to market of profiles manufactured by extrusion.

The experiment consortium is made up of three multi-disciplinary partners: the end-user from the manufacturing sector (Soprefa), a research organization and Application/Technology and HPC expert (UMinho), and the final one is an engineering and software consultant, a specialist in multiphysics simulations and numerical optimization (WDynamics).

The proposed validation case studies and dissemination strategy are expected to clearly motivate similar approaches.

Organisations involved:

End user and Application Expert: Soprefa Componentes Industriais, S.A.

Technology and HPC Expert: University of Minho

ISV: Wolf Dynamics

Partner University of Minho is part of the NCC Portugal.