Optimal CO2 Capture and Utilization Plant Design Through HPC

The design of CO2 capture and utilization (CCU) systems requires the consideration of a large number of design options and operating scenarios to attain optimum and realistic design solutions of low cost. The problem is computationally very challenging, due to the need to consider multiple different materials, different process structures and operating conditions. This experiment proposes the use of a parallel algorithm for integrated process design and controllability assessment of advanced CCU systems.

SECTOR: Energy

TECHNOLOGY USED: HPC

COUNTRY: Greece

The challenge

The solution

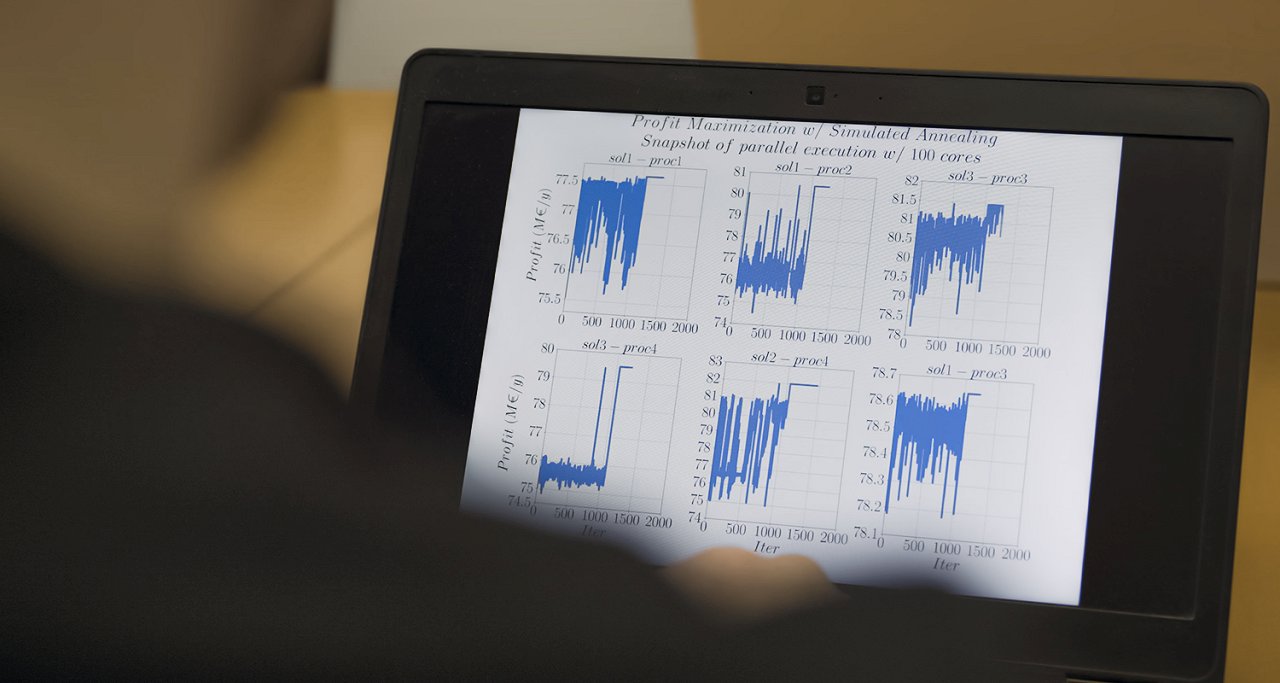

This experiment has resulted in computational tools that combine algorithms for chemical process design and control with approximate computing and parallelization techniques. A new set of capabilities related to advanced computing technologies has become available to Y Squared which increased the value and potential of their existing computational tools base. With the new developments, the discrete combination parameter space has increased by three orders of magnitude. The ability to solve the CCU problems simultaneously has conferred significant benefits compared to that of a sequential design approach (i.e. designing a utilization process after designing the capture process). The computational time to obtain the optimal design has decreased by approximately a factor of 50.

Business impact, Social impact, Environmental impact

Y Squared is engaged in the design of CCU processes, primarily serving as a consultant for the cement and quicklime industries. The demand for CCU plants is expected to rise sharply due to the strict CO2 regulations set internationally. The improved software provides Y Squared with a competitive advantage and market expansion opportunities in Greece and other European countries. The simultaneous design approach used in CCU resulted in a 6.5% lower cost per ton of calcium carbonate nanoparticles produced than the best, pre-project, sequential case. Due to the speed-up achieved through employing HPC, the company engineers managed to increase their efficiency and produce improved designs in a short amount of time. This allows Y Squared to take on more clients simultaneously and provide them with its customised and specialised services. The increased workload is expected to result in the creation of several job vacancies, as well as internship opportunities for young trainees to get exposure to chemical process design and modelling, advanced computing techniques, and HPC.

Benefits

-

HPC-aided CCU design achieves 6.5% cost reduction of calcium carbonate nanoparticles, making CCU more profitable.

-

1000x larger design spaces and 50x faster computing result in better designs which give Y Squared a competitive edge.

-

30% increase in revenue from design studies expected over the next 3 years.

Organisations involved:

End User: Y Squared Private Company

HPC provider: Yotta Advanced Computing d.o.o.

Technology expert: Centre for Research and Technology Hellas

Partner Centre for Research and Technology Hellas is part of the Greek NCC.