AI-Platform for Automated Training of Object Detection Models Based on CAD Data

Object detection with deep learning gains widespread use, with many innovative industrial vision applications arising recently. Due to the vast number of images required for training these models, many industrial applications are severely limited in the number of different objects that can be recognized. The approach within this experiment was to develop a procedure for automatic training of Artificial Intelligence object detection for large datasets of industrial parts.

SECTOR: Manufacturing

TECHNOLOGY USED: HPC, AI, ML

COUNTRY: Germany

The challenge

The manual assembly of devices consisting of many individual parts is a time-consuming, tedious and error-prone industrial process, which could in principle be supported by automated recognition technologies. As a typical example, Gabler is a manufacturer of production machines for packaging goods, each consisting of thousands of individual parts, either retrieved from an internal warehouse or obtained from external suppliers.

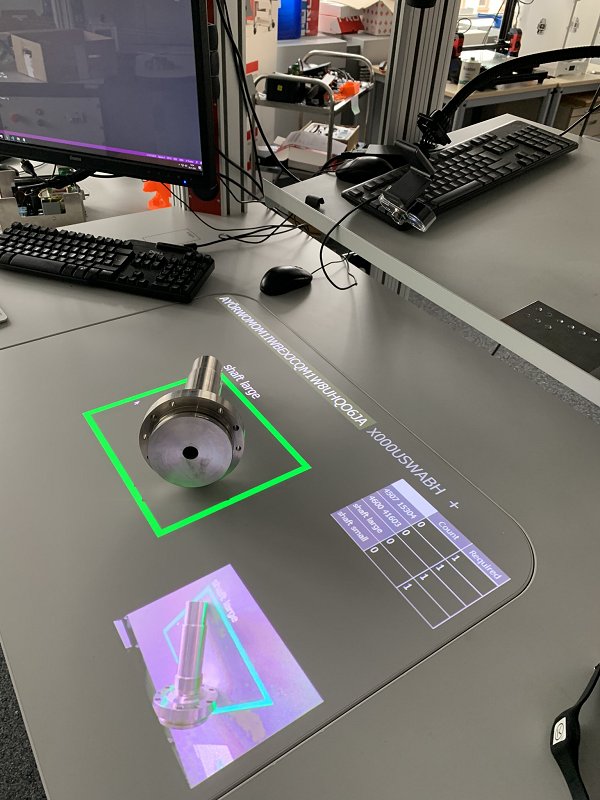

The part identification process could be assisted through automated object detection within an Augmented Reality (AR) application which outputs a list of potential candidates that limits the number of objects to check: The identification process becomes faster and easier, which saves the employee several minutes per identification task and the company multiple productive hours per day, in addition to reducing frustration within the workforce and avoiding errors in production.

However, while vision-based part recognition based on Deep Learning provides an easy and fast solution to the industrial challenge, the traditional way of building such tools is not cost-effective: huge amounts of images with corresponding labels are needed to train object recognition models. This is time-consuming and costly, thus severely limiting many industrial applications in terms of the number of different objects: Currently, only a few specific industrial applications such as autonomous robots or mass production quality control can benefit. Applications such as warehouse part detection, where one is dealing with thousands of individual parts, are still not economically feasible. Kimoknow seeks to speed up and simplify the generation of these AR applications in order to offer them to a much broader market, including companies like Gabler.

Taking a broader perspective, better human-machine co-working will be one of the most important changes that can facilitate the 4th industrial revolution. Vision-based assistant systems are an important component of that. AI-based computer vision has progressed considerably, but the efficient and cost-effective generation of machine learning datasets remains an open problem for these industrial use cases.

The solution

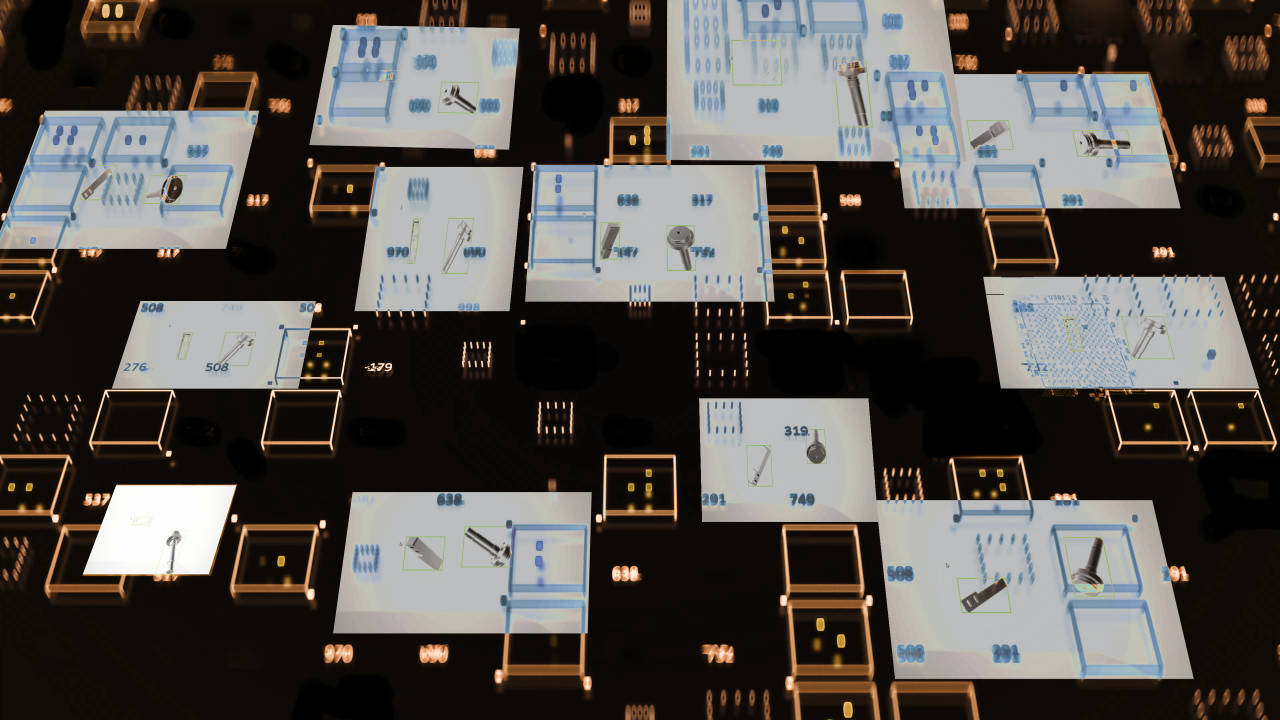

To make object detection for large datasets of industrial parts possible, Kimoknow automized the training of AI to a maximum. The approach for automatic AI training entails generating synthetic images from 3D CAD data in the first stage and then using these datasets to train an object recognition model. Both stages, particularly the data generation stage, have been parallelized and accelerated using multiple GPUs. To make the procedure scalable and available to a large number of industrial end-user companies (like Gabler) the solution is service-based and can be scaled modularly to available computing resources. By using the HPC infrastructure to generate the database for 1,000 parts in parallel, the computing time has been reduced from more than 100 hours to just 10 minutes. The manual process of taking real-world images would take more than 800 hours. The reduced time to generate an AI model allows very quick delivery to a customer and fast, cost-effective fine-tuning of the results. The use of on-demand HPC resources makes it possible to fine-tune the recognition model in a more cost-effective manner to achieve even better practical results.

Business impact/ Social impact/ Environmental impact

End-users of the Kimoknow AI detection system can enable their staff to be more efficient and enable them to work in increasingly complex environments. Therefore, jobs can be preserved as staff becomes more effective, and workers can be hired to do difficult tasks without extensive training.

The infrastructure built during the experiment provides Kimoknow with a business model that is highly scalable and can be backed by a cost-effective and energy-efficient HPC backend for the batched creation of fine-tuned object detection models in reduced time.

This serves the long-term business goal of Kimoknow to provide object detection services, where users can easily train object detection models based on their CAD data. Production and logistics companies such as Gabler Engineering benefit from Kimoknow services as they can generate object detection models for their own data with very low manual effort and implement object detection applications much more cost-effectively, thus creating AR tools to substantially improve their processes, as described above. Companies that are new to AI-object detection can see results for their own use cases a lot faster and therefore the entry barriers to new applications are dramatically lowered.

Benefits

- Through using the generated AI models, the end user Gabler can save several work hours each day with reduced search times, resulting in higher productivity and reduced worker frustration.

- Overall manual effort to generate an AI model for more than 1,000 parts is reduced from more than 800 hours to less than 10 minutes, thanks to automated training using HPC.

- Due to the reduced manual effort and the corresponding lower costs for the creation of AI models, Kimoknow can offer AI applications that were not economically feasible before.

- The fully automated services allow Kimoknow to target thousands of customers at once. Kimoknow expects to expand its business using the experiment results with steadily growing subscriptions and annual recurring subscription revenues.

- Overnight creation of AI models: from CAD upload to AR deployment.

Organisations involved:

End users: Gabler Engineering GmbH and Kimoknow UG

Domain Expert: SolidLine GmbH, Kimoknow UG

HPC Centre: Karlsruher Institut für Technologie