AI-Platform for Automated Training of Object Detection Models based on CAD Data

Presentation of the problem and objective of the experiment

Object detection with deep learning gains widespread use, with many innovative industrial vision applications arising recently. Due to the vast number of images required for training these models, many industrial applications are severely limited in the number of different objects that can be recognized. The approach within this experiment is to develop a procedure for automatic training of Artificial Intelligence (AI) object detection for large datasets of industrial parts.

Short description of the experiment

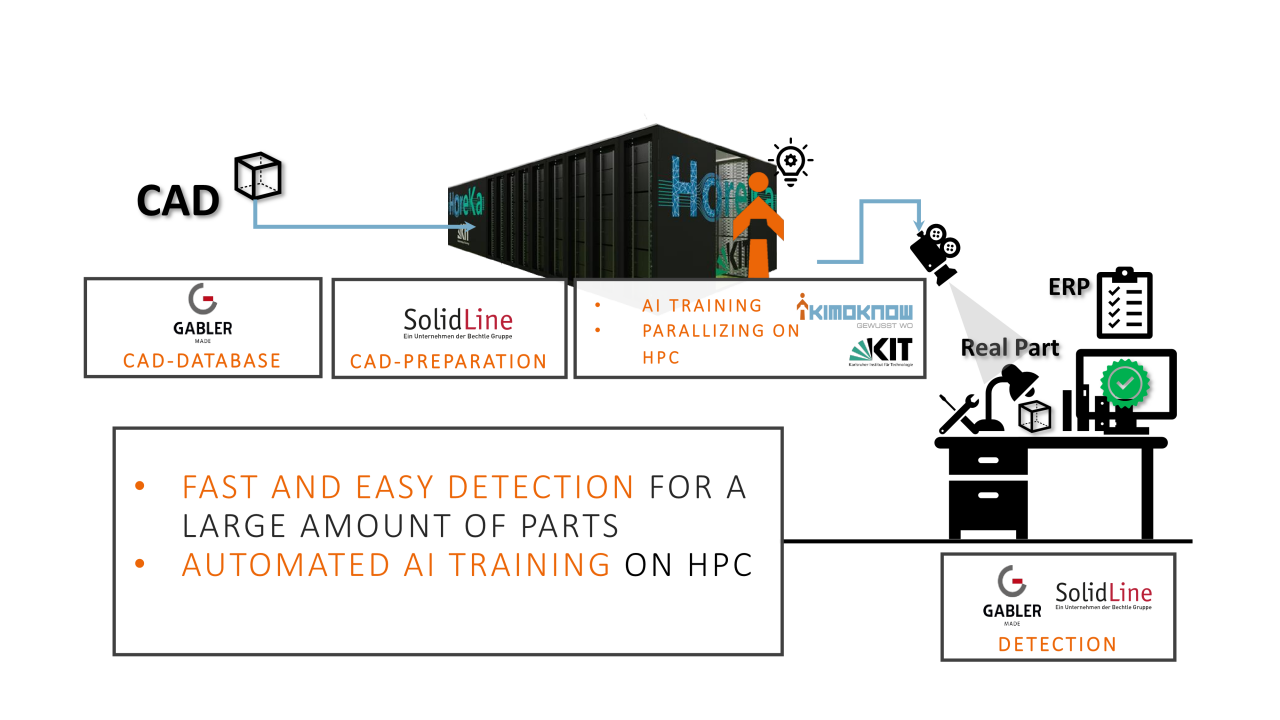

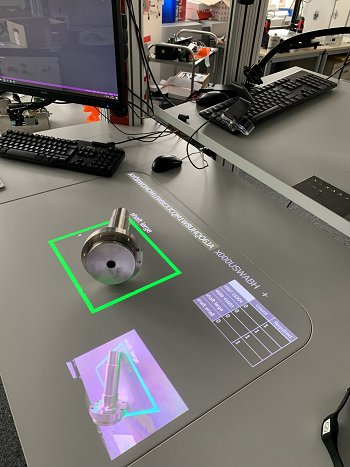

In this experiment, object detection models for industrial vision applications based on deep neural networks are trained only using 3D CAD models. The approach within this experiment is to develop a procedure for automatic training of AI object detection for large datasets of industrial parts. Due to the usually long computing times, the use of HPC is required for practical applications. This approach is the basis for a cloud-based service for creating object detection models based on CAD data. The reduced time per object detection model and the larger amount of object detection models empowers manufacturing SMEs to use object detection more easily.

UPDATE:

In the last months, partners have made great progress in automating their 3D model-based data labeling and object detection training pipeline. All the algorithms now run in parallel on high-performance computing centers (HPCs). This is an important step towards the partner´s vision that they will be able to deliver object-detection models for a customer’s CAD library overnight.

Organisations involved:

End users: Gabler Engineering GmbH and Kimoknow UG

Domain Expert: SolidLine GmbH, Kimoknow UG

HPC Centre: Karlsruher Institut für Technologie