Cloud-based HPC processing for knowledge generation in camshaft manufacture

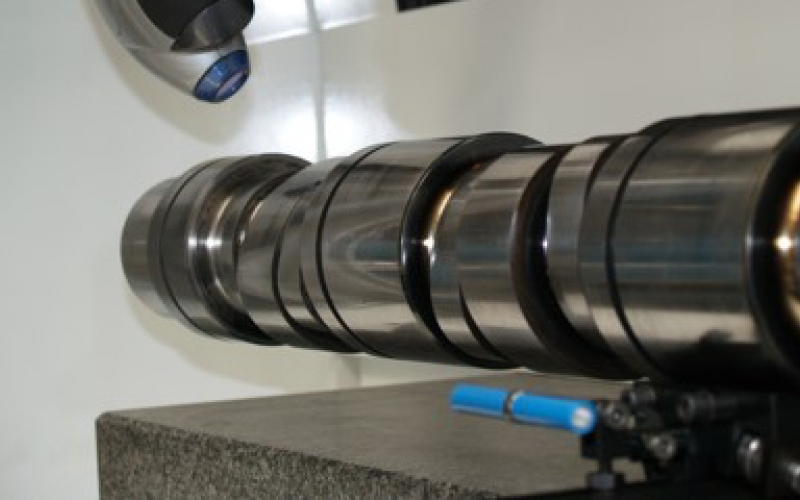

EPC Group Europe is headquartered in Spain. It specialises in the manufacture of large camshafts (over 2 meters long) for use in the naval industry, agriculture, military, generators, and other sectors.TRIMEK is a Spanish SME founded in 1993. TRIMEK is one of the main manufacturers of metrological systems and solutions worldwide, and is the 4th worldwide provider and the leading company in the Basque Country and Spanish markets of Coordinate Measuring Machines (CMM).

The Challenge

EPC manufactures more than half a million camshafts every year. The company needs to ensure that it produces high-quality parts. Monitoring of the manufacturing process generates a massive amount of data which could be used as a basis for machine learning to improve the production process. However, current software solutions are not able to fully process the data fast enough, so the potential knowledge that may be generated from it cannot be exploited.

In order to function alongside a busy production line, the solution requires significant computational power, together with the application of novel machine learning technologies.

The Solution

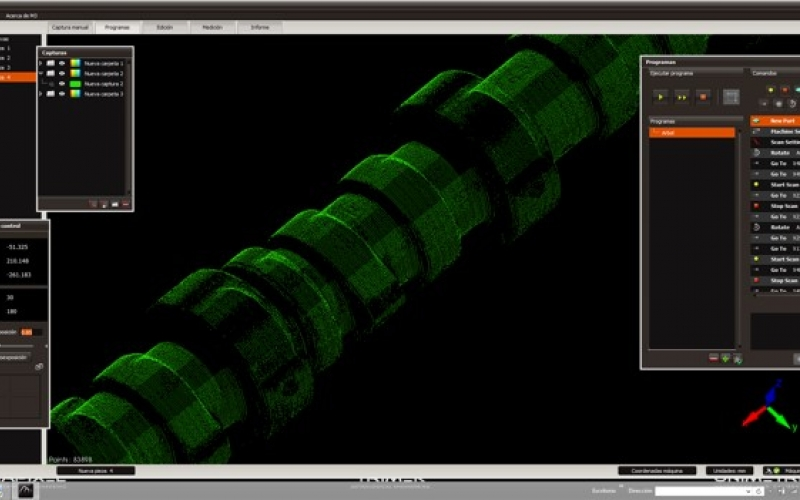

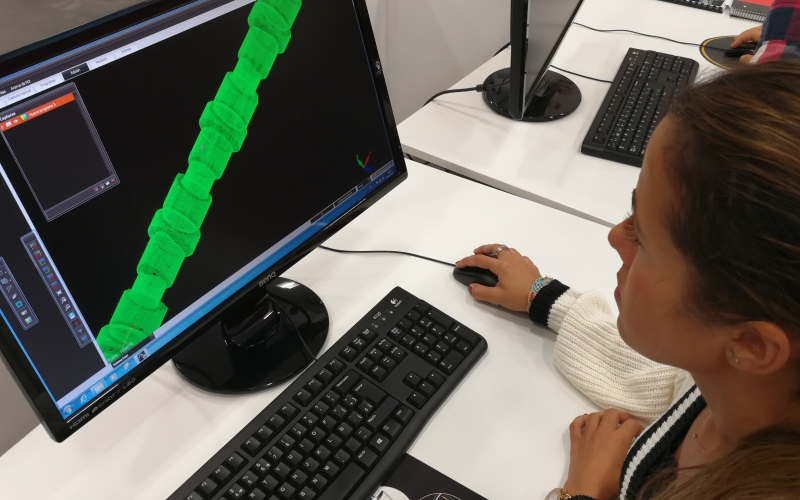

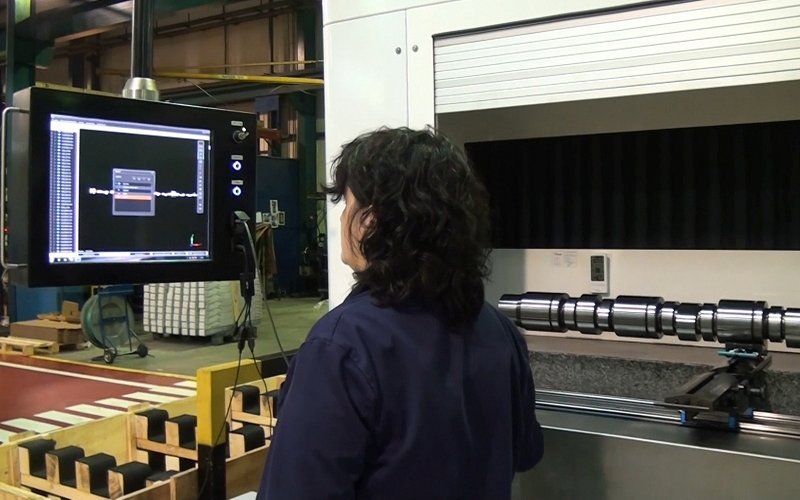

TRIMEK developed a metrological module of its M3 software, which enables the use of big data resources for data analysis. The new module is able to analyse scanning and measurement data and compare parts much faster than before by using cloud-based HPC. The production process is therefore more time-efficient. The time savings enables more of the produced parts to be checked in the same amount of time, increasing the overall production quality.

Reducing the processing time for data analysis allows a higher knowledge and control of the quality of the production process and of its needs, such as maintenance requirements. By using this system, the end-user receives a higher-quality product, saving time and money, leading to benefits for their own client.

Business Impact

TRIMEK, as service expert, developed a new software module for statistical analysis. Due to the optimized dataprocessing software developed in this project, TRIMEK expects an increase of 20% in new licences sales.

EPC has tested and used the new M3 capacities within their production site, proving its ability to improve production capacity and speed. In a short time, the expected benefits to the internal production process will reduce the number of defective parts to almost zero, resulting in a cost reduction of €1.5M over the next five years.

CESGA will exploit the experiment results in its big data platform, which has been analysed and improved to fulfil the requirements of its commercial customers. As initial step, CESGA has created a white paper to show the capabilities of the infrastructure to use as marketing tool to attract other companies to use it. CESGA expects to be able to increase its SME projects and services in the next years to reach the strategic indicators for 2020.

Benefits

- 20% increase in turnover over five years for TRIMEK.

- EPC can save €1.5M over five years using the new solution.

- The number of defective parts is reduced to almost zero.