HPC Cloud-based analysis for optical control in manufacturing processes

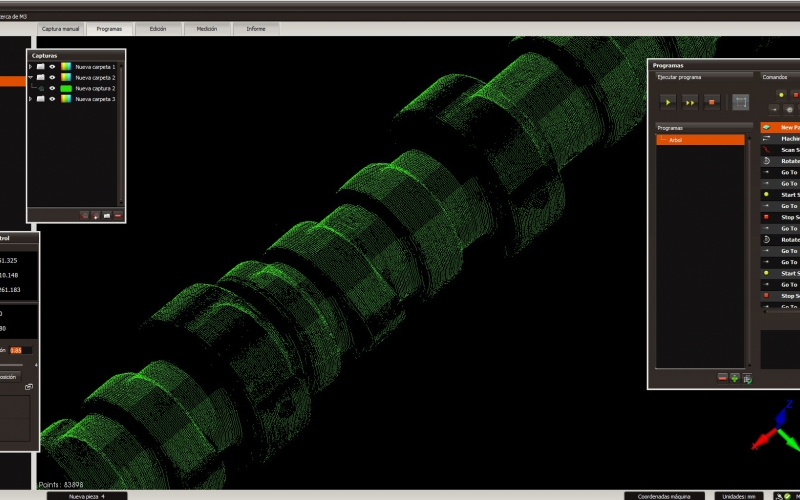

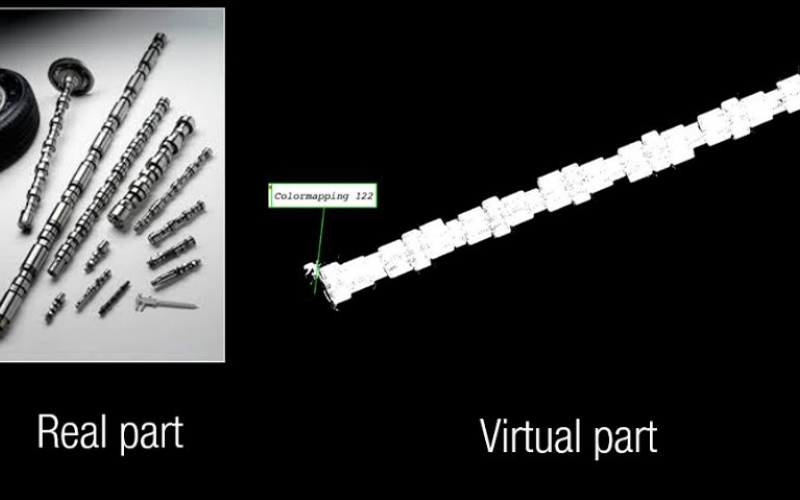

EPC is a Spanish SME specialising in the manufacture of camshafts. These are critical components in high power engines where dimensional tolerances are very small. For this reason, EPC is always working to improve its quality-control process, integrating the latest innovations in hardware and software. The integration and exploitation of 3D optical scanning systems for dimensional quality control in manufacture results in significant benefits in terms of time and dimensional information generated compared to traditional tactile technologies. However, the use of such systems has to overcome issues associated with the processing, analysis and storage of the huge amount of data acquired. For example, a typical file size is around 300 Megabytes, representing 15 million points. This means that a single company generates several Terabytes of information in short periods of time to be processed by a metrology service provider such as Unimetrik. At the same time, metrology software developers such as Datapixel have to work on the optimisation of their processing algorithms to enable quicker access to the information contained in the data collected. The use of Cloud-based HPC has the potential to provide a detailed and quick analysis of manufacturing processes enabling significant improvements in the control of quality in production processes.

The Challenge

The challenge of this case study is to develop a data-processing service which enables manufacturing companies, particularly SMEs, to control manufacturing processes to a very high level of accuracy using optical scanning techniques. This requires intelligent, fast and intensive analysis of manufacturing quality using 3D digital information of the parts to be manufactured. The combination of scanning, measurement and analysis has the potential to enable the early identification of any deviation in the manufacturing process from the required design parameters and of the necessary corrective measures to be taken.

The Solution

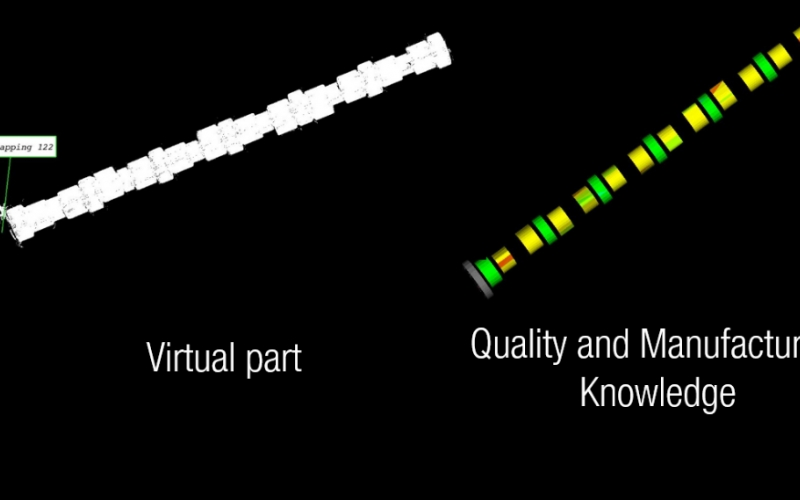

Through the use of Cloud-based-HPC resources, the participants in this case study have been able to exploit advanced optical systems and exploit the information in the data gathered. New methods of analysis such as large-scale geometry extraction and temporal analysis of the dimensional quality of large batches are now possible. Moreover, traditional tasks such as reverse engineering are now optimised enabling the much faster generation of control data for the production line. This allows the generation of additional information concerning the manufacturing quality at both the part and system levels. Geometry extraction and reverse engineering enable the computation of information concerning the quality of final parts, detailing the size and shape of components and comparisons against the nominal expected value. When dealing with large batches, the output data are related to the evolution of the manufacturing quality of the production line enabling the detection and prediction of when a defect will occur due either to a lack of machining performance or to damage to machining tools.

The Benefits

The use of the HPC-cloud-based service enables a reduction in the time needed to extract dimensional information from 5 minutes to 1 minute. Due to this time reduction:

- Unimetrik will increase its service business by 30% and its portfolio of international customers by 20%. This is expected to lead to an increased turnover of €400K over the next five years due to the commercialisation of these advanced services and the creation of two new positions within the company.

- Datapixel, expects an increase of 25% in new licences, representing an additional turnover of €750K over the next five years, due to the commercialisation of the optimized data-processing software developed in this case study.

- The end-user, EPC, expects to improve the quality of its manufacturing process reducing the production of defective parts down to 0%. This would result in a cost reduction of €1.5M over the next five years.

Furthermore, the HPC provider, CESGA, will be able to offer its services to new users working in the manufacturing domain. In particular, it will exploit HPC applications in the virtual metrology field.

Companies Involved:

End-user: EPC

Domain Expert: Unimetrik

ISV: Datapixel

HPC Provider: CESGA