High-Fidelity Modelling of a Hydrogen-Fired Industrial Combustor

This experiment developed a computational platform for virtual testing of industrial combustors using High-Performance Computing (HPC). It used an advanced modelling strategy based on high-fidelity numerical simulations and HPC-based data analysis tools to obtain quantitative information on combustion performance and efficiency. It pursueded the generation of digital tools that can reduce manufacturing costs and accelerate the deployment of low-carbon technologies for power generation.

SECTOR: Energy

TECHNOLOGY USED: HPC, CFD Simulation

COUNTRY: Spain

The challenge

EMC develops burners for energy production plants. EMC burners can operate with all types of liquid and gaseous fuels from diesel or natural gas to alternative fuels.

The EU commitment to achieve net-zero greenhouse gas emissions by 2050 is driving the power generation industry to prioritise the development of low-carbon technologies. Among different solutions, green hydrogen and hydrogen-enriched fuels have a significant potential to enable the transition to a clean, low-carbon energy system. This transition to more energy-efficient, lower pollution emitting, (particularly considering NOx) power generation systems create challenges for all industries in the market and in particular for SMEs in the sector. To stay competitive, EMC requires targeted and efficient digitalization.

The solution

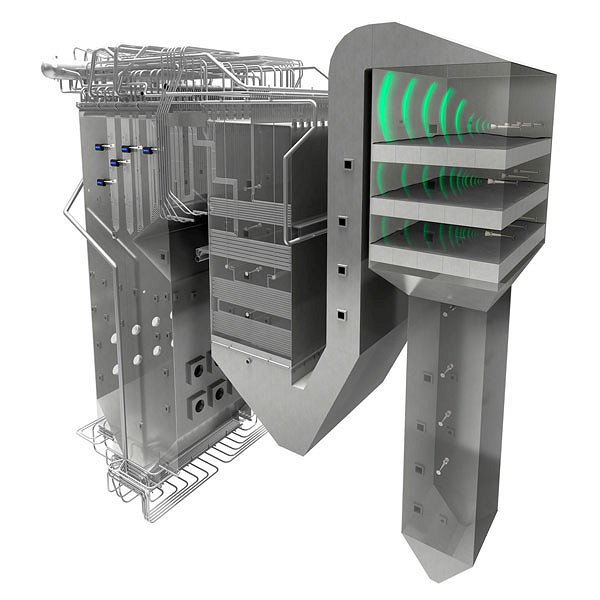

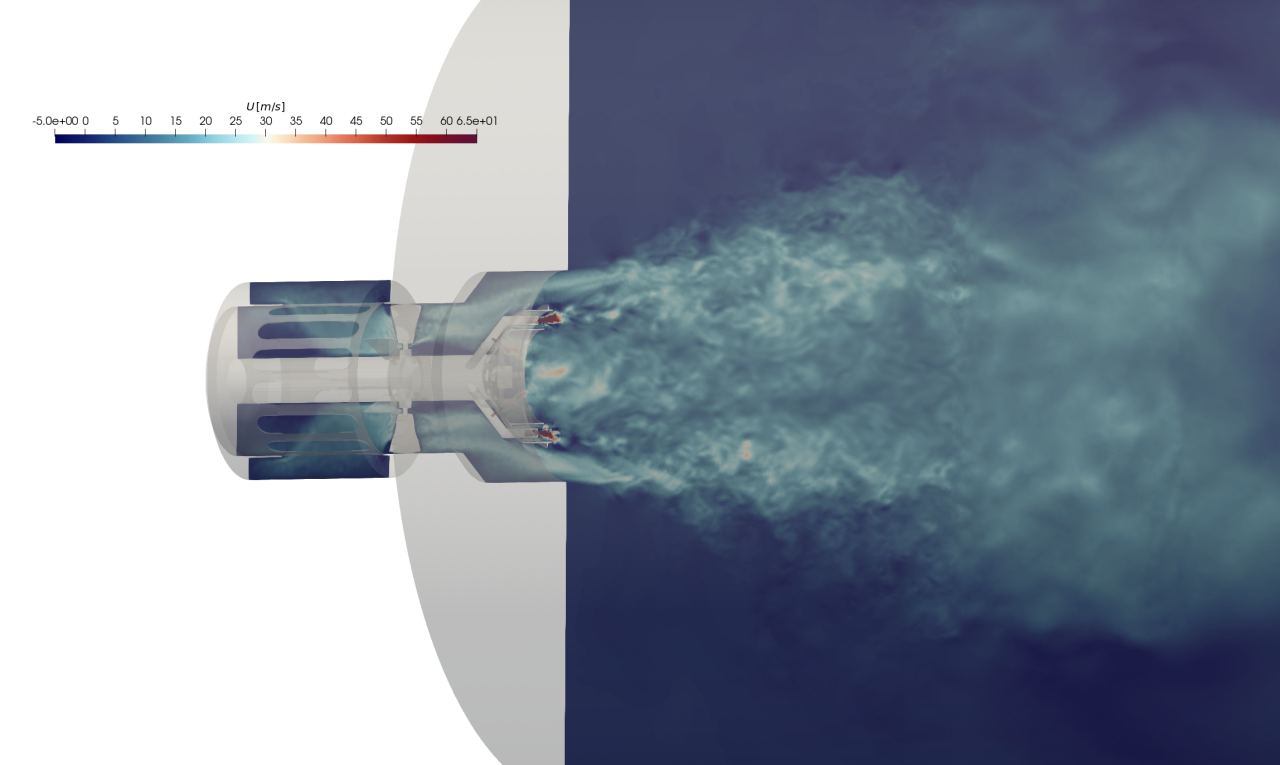

The experiment developed a platform for virtual testing of industrial combustors using HPC and advanced modelling strategies to obtain quantitative information about combustion performance in terms of combustion dynamics, pollutant formation, and burner operability for hydrogen-enriched conventional fuels.

This platform is integrated into EMC’s design and optimization cycle for its new low-NOx injectors for hydrogen-enriched mixtures. The experiment provides a multidisciplinary approach based on physical tests and high-fidelity numerical simulations, with the goal of accelerating the deployment of low-carbon technologies for power generation while reducing the duration of the design cycle and overall costs. This is possible only thanks to HPC since combustion simulations are particularly expensive in terms of computational requirements and thus prohibitively slow on non-HPC systems. Digitalization based on advanced HPC-enabled simulations is the key to increasing EMC’s competitiveness.

Business impact, Social impact, Environmental impact

-

EMC will save significant costs associated with traditional physical testing. It reduces the need for expensive prototypes, testing equipment, and specialised personnel. The estimate of savings in the design cycle of a new combustor is around €50,000.

- With virtual testing, EMC can accelerate the development of new industrial combustors, achieve faster time-to-market, gain a competitive advantage, and increase its market share. Estimations show that around 4 to 6 months of testing time could be saved.

- Enhanced innovation: The computational platform can allow EMC to test new and innovative designs of industrial combustors that may not have been feasible with traditional testing methods, reducing fossil consumptions and emissions.

Benefits

- Shortening time-to-production and time-to-market by 20 %.

- Gaining hydrogen technology know-how through design comparison, enabling optimized product releases, and reducing maintenance costs by 25% through numerical simulation platform usage.

- Expanding EMC’s consultancy services and offering high-fidelity numerical tools, enhancing revenue streams with virtual testing, generating approximately €100,000 in the first year and increasing turnover by 5%.

- Jump-starting the digitalization for burner design and optimization, reducing design costs by 30% and employee costs by 5%.

- Establishing EMC as a technologically advanced SME in the combustion field, accelerating product development through digital tools and making EMC a reliable R&D partner with experimental and numerical know-how.

Organisations involved:

End user: E&M Combustion

HPC Provider & Expert: Barcelona Supercomputing Center

Partner Barcelona Supercomputing Center is part of the Spanish NCC.