HPC-based Engineering Design for Control of Smoke in Subway Tunnels

Design of smoke control systems and emergency strategies for subway tunnels in the event of fire represents a very challenging task, a non-negligible part of the engineering efforts as well as the costs of civil works and systems aimed at human safety. The objective of the experiment is to make available an innovative process to efficiently design smoke control systems and emergency strategies by using high-fidelity 3D Computational Fluid Dynamics (CFD) simulations and on-demand HPC.

SECTOR: Transportation, Civil Engineering

TECHNOLOGY USED: HPC, CFD Simulations

COUNTRY: Italy

The challenge

Over 500 people died between 1987 and 2003 in several subway tunnel fires across the world. Since these catastrophic events, new specific rules, guidelines, and protection strategies have been developed by the national and international authorities to optimise the emergency evacuation of tunnel fires via proper control strategies of fire smoke.

Design of smoke control systems and emergency strategies for subway tunnels in the event of fire represents a very challenging task. In this context, traditional methods currently in use by TECNOSISTEM and similar engineering companies operating in the construction sector are based on trial-and-error and approximate methods, focusing on a limited number of fire scenarios. These mostly use simplified simulation tools and are therefore neither cost-effective nor accurate, with potential adverse consequences in terms of passengers’ safety during the evacuation phase.

Consequently, the current design approach is sub-optimal for a number of reasons, including increased personnel costs and design timelines due to lack of process automation and limited computer hardware resources to accurately model the complexity of the physics involved. In addition, an inefficient design of smoke control strategies inside subway tunnels very often leads to increased costs for civil works for hosting sub-optimal, oversized ventilation fans and increased risk factors for train passengers.

The solution

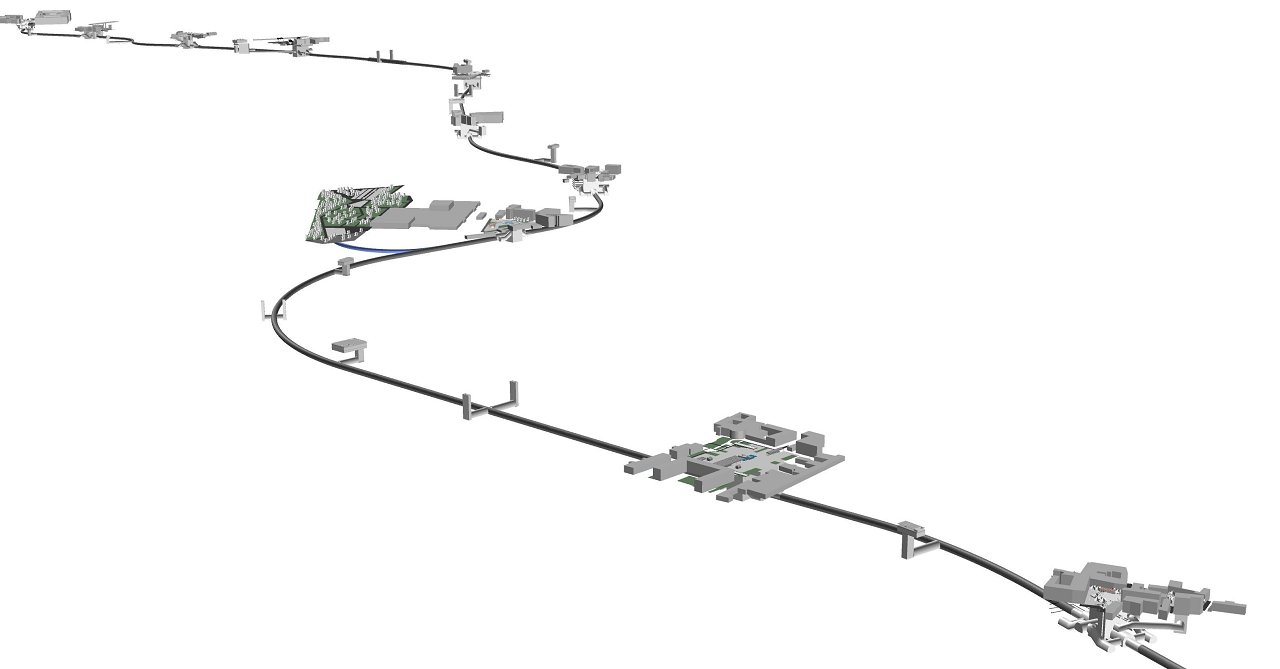

The solution introduced by this experiment was the development of a unique CFD-based framework leveraging HPC resources to simulate large CFD transient models of a complete subway node in the event of fire using a full 3-dimensional (3D) approach. This is contrary to the traditional design practices, based on iterative and approximate design methods mostly using 1-dimensional (1D) simulation codes.

This innovative process enables the efficient design of smoke control systems and emergency strategies in tunnels based on a detailed virtual representation of the tenability and visibility field in the event of fire and a time-varying control of the ventilation systems, optimized for the different phases of the fire itself.

The process was successfully validated with a real subway line to be built in Southern Italy and designed by TECNOSISTEM.

Business impact, Social impact, Environmental impact

The solution proposed by this experiment provides an immediate benefit to TECNOSISTEM by increasing market competitiveness via a significant internal cost saving due to the optimized design process. By extension, the newly HPC-based framework offers an attractive solution for TECNOSISTEM customers including construction companies as well as communities, since the new design methodology allows for a substantial downsizing of ventilation fans and silencers, thus reducing the excavation volumes and civil work related costs.

ENGYS plans to make the HPC interface developed for the experiment available in the proprietary software HELYX and will target any potential SME operating in the rail construction and engineering sector to provide a unique design framework via high-fidelity CFD.

Finally, the adoption of the newly developed HPC-based methodology will have a societal impact in terms of increased safety since a safer emergency design will result in a considerable reduction of risk factors for passengers in underground mass transport.

Benefits

- Estimated average internal cost saving for TECNOSISTEM ranging between 7% and 15% for the design of a typical subway line.

- Estimated increase in turnover for TECNOSISTEM between 4% and 7% in five years due to the greater effectiveness and induced cost reduction of the civil works.

- New potential market segments for ENGYS to offer an HPC-based solution for engineering and construction companies.

- Cost reduction for excavation and equipment for construction companies and communities which can range from €3 to €9M for a typical subway line.

Organisations involved:

End User:TECNOSISTEM S.p.A.

ISV: ENGYS S.R.L.

HPC Center: CINECA