HPC for Canned Food Dynamics

Presentation of the problem and objective of the experiment

Canned food consumption has recently experienced an important demand increase, especially due to COVID-19 pandemic, which has challenged each supplier to strike their processes to improve their production rates.

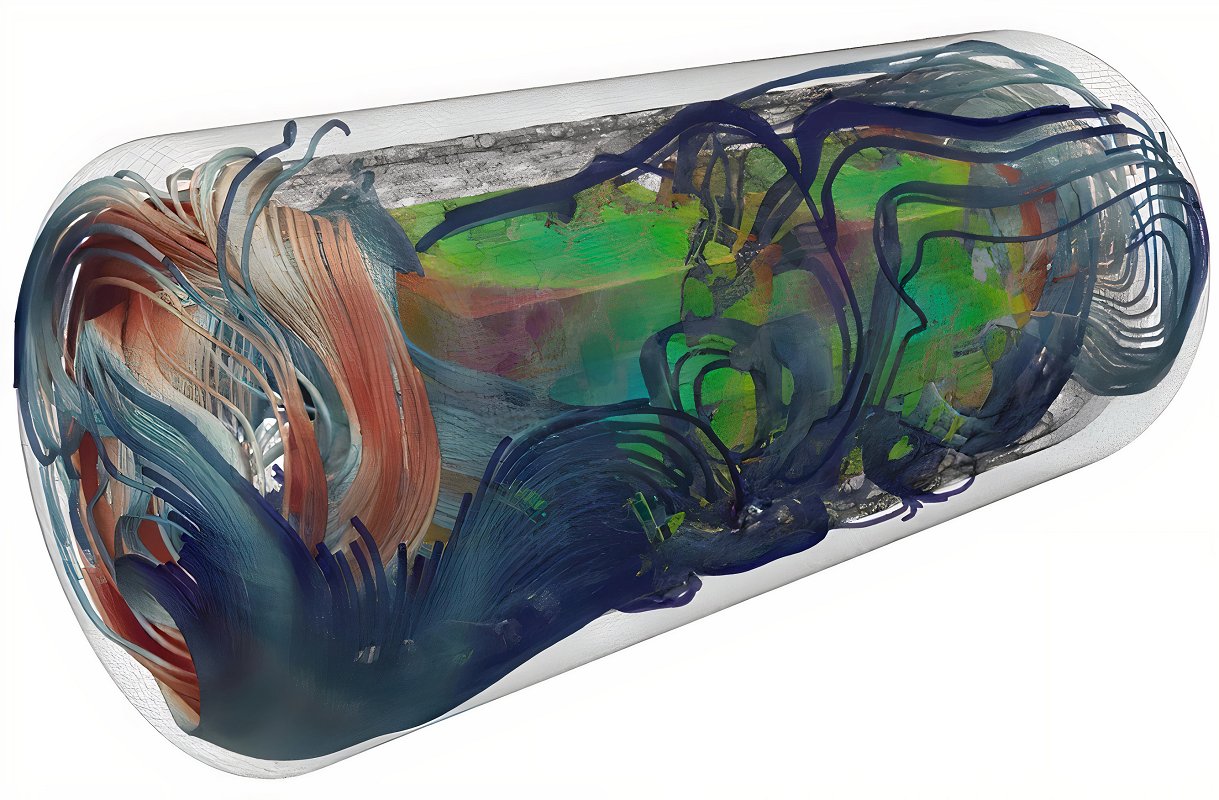

One of the most sensitive processes of this sector is sterilization, where autoclaves are the main equipment, and only their design can easily take 4 months, since highly trained personnel is required, as well as powerful CFD tools and computing power to properly study the heat transfer inside this equipment, considering the size scales.

Short description of the experiment

This project proposes to develop an innovative tool to aid the design and manufacturing processes of autoclaves, using OpenFOAM as the software to develop CFD simulations, as well as HPC to overcome the computational processing limitation barriers arising from the large differences on size scales inside autoclaves, and the multiple variables to study when assessing thermal performance.

Through an intuitive web-based graphical interface, the necessary skills to design and operate thermal systems will be reduced, since all the complex calculations are done automatically by CFD with the parameters obtained directly from the GUI. Thus, the system would be able to be operated by people without knowledge or experience within these technologies.

Organisations involved:

ISV: SDEA Solutions S.L.

End User: TACORE

Technology expert: ANFACO-CECOPESCA

HPC Provider/Center: CESGA

Domain Expert: Faculty of Engineering of University of Porto

Partner CESGA is part of the NCC Spain.