Improving Graphene-Epoxy Mixing Recipes with HPC Simulations

Presentation of the problem and objective of the experiment

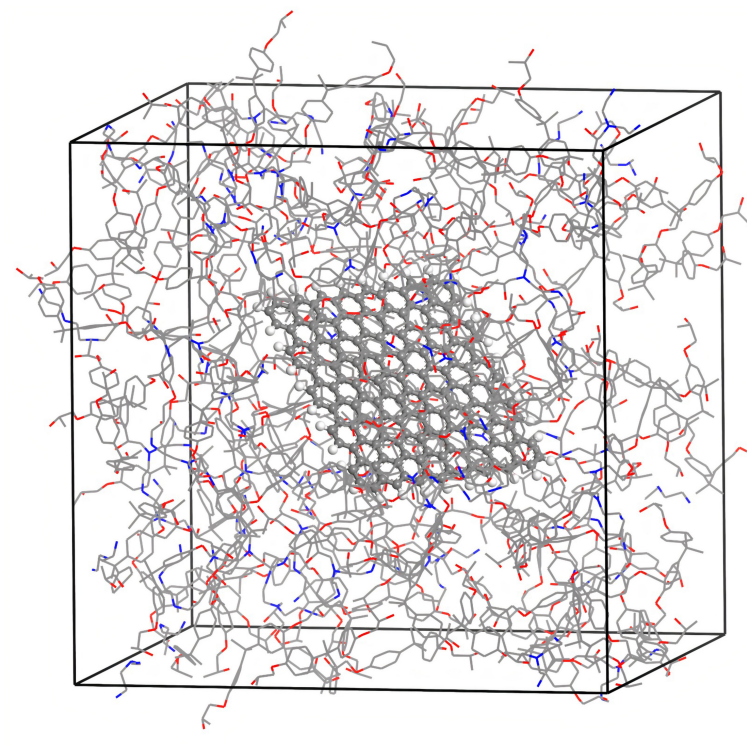

Obtaining highly dispersed graphene sheets and improving their interaction with the epoxy matrix are the main challenges to producing high-performance graphene reinforced epoxy composites. Functionalization of graphene structures with oxygen-containing groups is crucial to overcome these challenges. This project aims to optimize these parameters using theoretical methods in HPC systems to simulate pathways to a more homogeneous and repeatable material manufacturing process for epoxy/graphene oxide nanocomposites for the composite industry.

Short description of the experiment

This project will help the industrial partners for parameter optimization such as constituent type and ratio in epoxy-GO nanocomposites by the theoretical studies performed by HPC partners. The state-of-the-art of graphene-epoxy composites with improved properties will be optimized by controlling the GO structure, functionalization percentage, epoxy polymer structure and cross-linking density. The results of the experiment will be the optimization of the GO functional groups and mass percentage of functionalization to maximize the physical and mechanical properties of epoxy-GO nanocomposites. Parameters for a homogeneous and repeatable material producing process will be determined which is critical output for companies out of this project studies.

Organisations involved:

Technology Expert: Alti Dynamics

HPC Expert: METU

HPC Center: TUBITAK

End User: Nanografi

Partner TUBITAK is part of the NCC Turkey.